Survive By Quality, Development By Credit, Efficiency By Management

Home / All / 3 in 1 Decoiler Straightener Feeder / GLK4 3 in 1 Coil Feeder for Press /

GLK4-400 Coil Feeder Machine With Uncoiling Leveling Feeding For Stainless Steel Coil Sheet Punching

GLK4-400 Coil Feeder Machine With Uncoiling Leveling Feeding For Stainless Steel Coil Sheet Punching

| Categories | GLK4 3 in 1 Coil Feeder for Press |

|---|---|

| Brand | HongEr |

| Model | GLK4-400 |

| Function | unwinding straightening and feeding |

| Feature | with coil car loading metal sheet |

| Name | unit coil feeder for pressing |

| Compact | press machine |

| Usage | auto metal parts stamping |

| attribute | 3 in 1 servo feeder machine |

| Update Time | Apr 16,2025 |

Detail Information

GLK4-400 Coil Feeder Machine With Uncoiling Leveling Feeding For Stainless Steel Coil Sheet Punching

Description

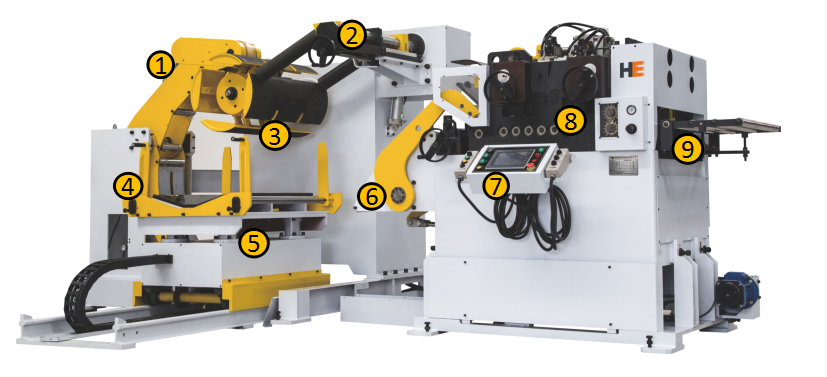

1, Pressing arm: with pneumatic power. Especially the PU pressing roller is with motor drive.

2, Limited arm: by hand wheel control.

3, Decoiler mandrel: hydraulic expansion.

4, Supporting arm: support the metal steel sheet coil, so as to protect the uncoiler mandrel.

5, Coil car: rubber cushion for non-slip when loading the metal coil.

6, Inlet feeding arm: clamp the metal strip and feeding it into straightener (leveler) smoothly.

7, Control display screen: operate the coil feeder machine with electrical control.

8, Straightener: straightener rollers are adjusted by worm and gear.

9, Outlet: outlet for strip feeding out.

specification

Model |

GLK4-400 |

|||||

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||||

Coil width(mm) |

70-400mm |

|||||

Coil thickness | 0.6-6.0mm | |||||

Coil weight | 3000kg | |||||

Coil I.D.(mm) |

480-520mm |

|||||

Coil O.D.(mm) |

1500mm |

|||||

Max. speed | 16-24 m/min | |||||

Feeding accuracy | +/- 0.15 mm | |||||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||||

Power | 380V 60HZ | |||||

Expansion | Hydraulic | |||||

Pressing arm | Pneumatic Type | |||||

Servo motor | AC5.5 | |||||

Uncoiler motor | AC2.2 | |||||

Application

GLK4 automatic servo coil feeder

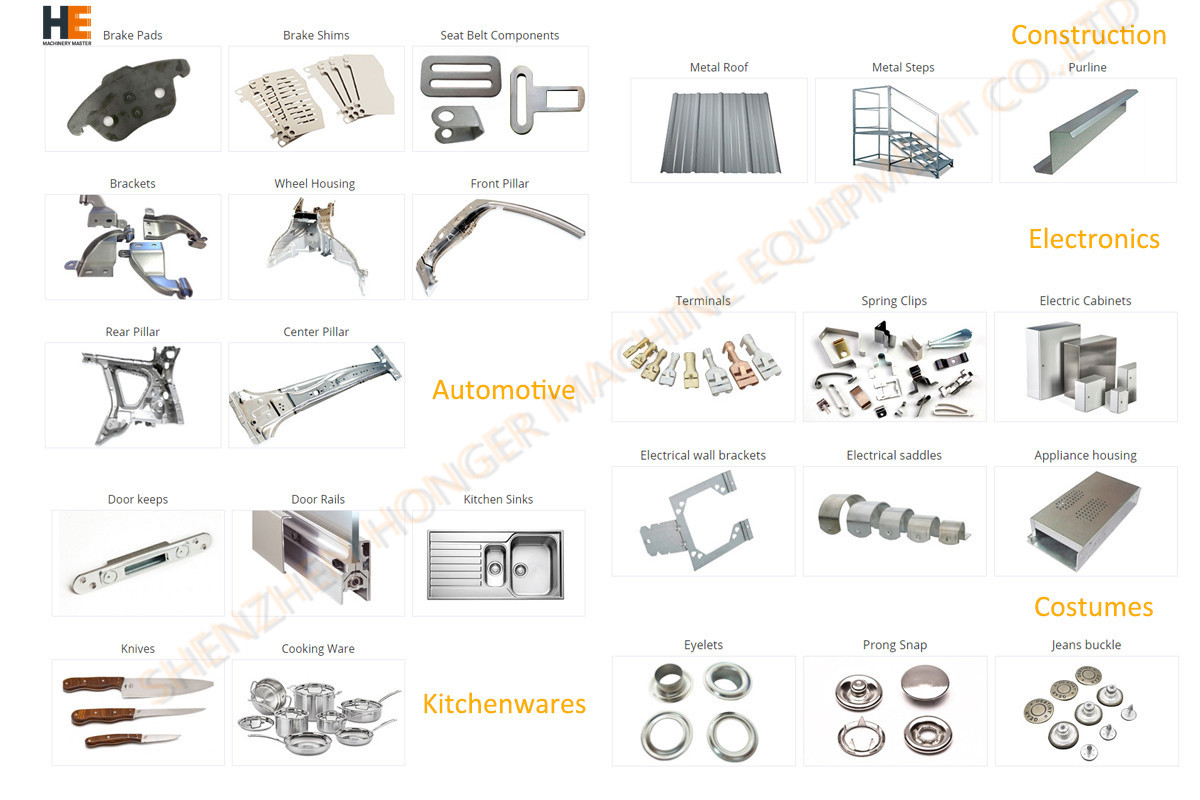

GLK4 uncoiler straightener feeder machine which is widely used in metal stamping feeding line for metal parts stamping.

It is popular in electric appliance, construction, furniture industry, automotive stamping.

This 3 in 1 auto coil feeder machine can be equipped with press machine, cutting, shearing.

GLK4-400

for unwinding, straightening and automatic feeding in metal stamping line will be equipped with mechanical press machine

exported to Malaysia stamping manufacture

Solution Sugeestion:

3 in 1 decoiler straightener feeder + press

Package & Delivery

About us

www.hongerjixie.com

We are manufacturer of metal stamping equipment like decoiler, straightener, feeder machine for metal coil handling solution in press room.

Our equipment is for automation feeding system in press room to realize automatic stamping.

The related machines of us are including 3 in 1 unit coil feeder, 2 in 1 uncoiler and straightener machine, single decoiler machine, horizontal uncoiler machine, straightener machine, servo coil feeder machine, mechanical press machine, etc.

Our machines are adopted in automotive stamping manufacturer ( automobile manufacturer), construction metal parts manufacturer, furniture metal parts manufacturer, kitchen ware metal parts manufacturer, costume eyelet ( button) manufacturer, electronic parts stamping manufacturer, etc.

For metal punching / metal stamping / metal pressing cases, we could offer you best solution with whole production line including uncoiler, straightener, servo coil feeder, power press machine and progressive molds. The machines choosing will be according to your metal coil's specification and the technical requirement of your product. Our tooling engineer will design mold for you according to the CAD drawings or samples of your metal parts. After stamping tooling designed, we will know the tonnage and type of mechanical press machine you required and the sized of metal coils you need.

Our machines has been exported to many countries and areas so that if you need to have a inspection of our metal stamping equipment, you may visit our clients' factory under their permission.

Also we will test and do 100% inspection of our machines before shipment.

Your visiting to our factory are warmly welcomed.

Related Products

Please send your message to us

- Tel

- *Title

- *Content

subscription

navigation

Contact Person

- Name:

- Sophie

- Tel:

86-755-28372363

- Email:

- sophie@he-machine.com

- WhatsApp:

- https://wa.me/8613824319691

- Address:

- F1601-02, A4 Bldg Zhujiang Plaza,No.9009 Longxiang Blvd,Longgang,SZ,518172,CN